If your thoughts turn to fine jewelry at this time of the year, one of the best places to find it is at Peñaloza & Sons, a family-owned business that’s been around since 1958. Gold, diamonds and sapphires set in beautifully designed bracelets, rings, necklaces, earrings and more glitter in the display cases. And it’s not just a store. As manufacturing jewelers, the company’s craftsmen can design a custom-made piece of your dreams, restore a family heirloom, repair a valued item or appraise what you already have.

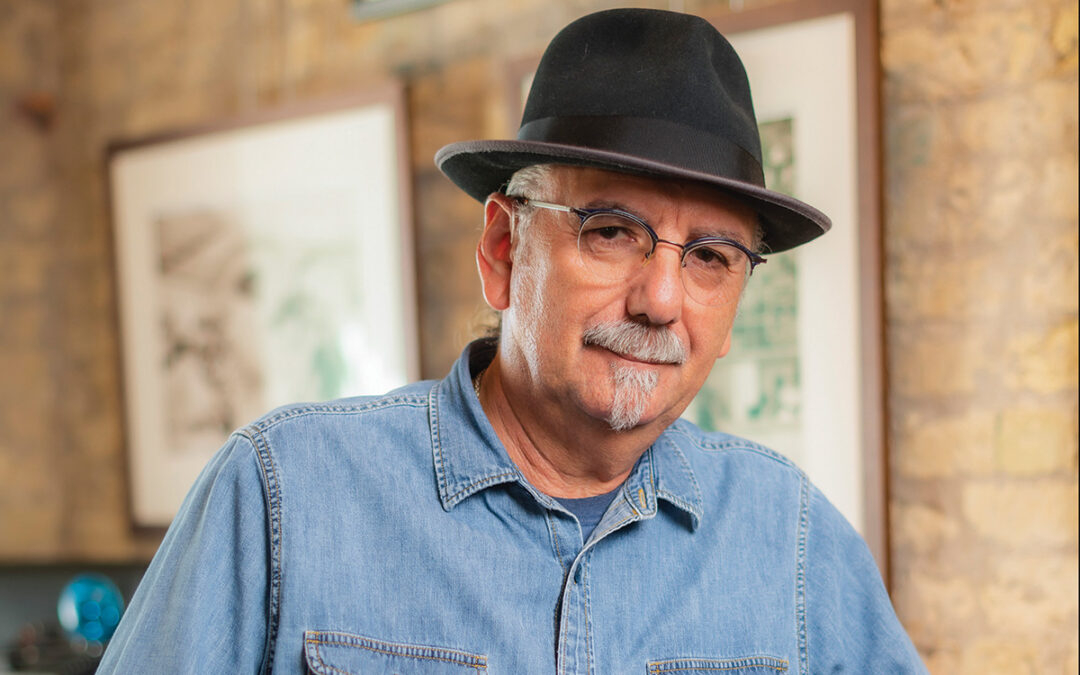

The Peñaloza men have been in the jewelry business for four generations, starting with the grandfather of current owners Paul and Phillip Peñaloza. Their father, Charles, founded the present company and ran it almost until his death in 2002. Two other family members also work on the premises — Paul’s wife, Alice, and Phillip’s son, Charles Michael. Collectively, they have earned the trust and loyalty of customers with their knowledge, service and quality craftsmanship.

While Phillip runs the manufacturing shop, certified gemologist Paul Peñaloza is the guy who deals with the customers, designs jewelry and takes care of the financial side of the operation. Though he grew up in and around his father’s shop, as a young man, Paul decided that retail wasn’t his cup of tea. After graduating from UT Austin with a business degree, he joined the Air Force to realize his dream of becoming a pilot. For several years, the young officer flew a C-130 military plane “all over the world,” transported top-secret nuclear weapons around the country and delivered humanitarian aid to hurricane-stricken Caribbean islands. But when the Air Force reassigned him to a desk job, Capt. Peñaloza quit to return home and rejoin his father’s company. He went on to earn an MBA from the University of the Incarnate Word and a master’s degree in operations management from the University of Arkansas-Fayetteville.

Can you describe the type of design that Peñaloza & Sons specialize in?

Most of the pieces we design are a little more classic in their look, a little more tailored. These are the kind of pieces that we feel will be in style 10, 20, 50 years from now. We mainly work with better-quality goods — diamonds, 18-karat gold and platinum — but we’ll work in 14-karat and silver if needed. If I can repair a pair of costume earrings for a customer, I will. We consider ourselves full-service manufacturers.

You also sell other manufacturers’ jewelry. Could you mention some brand names?

We carry a number of better-quality brands, such as Simon G. and Bertolucci watches that are Italian-designed but manufactured in Switzerland, which I think is the best of both worlds; also diamonds from different manufacturers. In our display cases, probably 15 to 20 percent of the pieces are our designs, either one-of-a-kind or limited-edition pieces, while the rest are from other manufacturers. However, we do a lot of custom work, so in overall sales, some 40 to 50 percent are pieces we either designed or redesigned.

What are some specific challenges of this kind of business?

Our inventory is very expensive, so of course we have to keep a close eye on managing that. Security is extremely important to us. We are happy to be in Castle Hills, where the police are very responsive, and we have a good security system. In terms of customer service, everything that we handle is extremely valuable to us, whether it’s a little silver ring or a huge diamond. To the customer, each piece has a sentimental value, and in jewelry sentimental value can override everything. We once spent $20,000 restoring a ring for a woman, a ring that had belonged to her grandmother but that had been taken apart by various family members. She wanted it restored to its original condition, no matter the cost.

How has technology changed jewelry manufacturing?

A great deal. For instance, one of the machines we have now, a $30,000 machine called the laser welder, has made repairs much easier. Using laser technology we can work on a piece of jewelry right next to a stone that doesn’t tolerate heat without removing the stone. An example would be an emerald ring that may need re-pronging. In the past, we had to remove the emeralds, do the prong work and then reset the stones. Now we can do all that with the stones in place; makes it faster and cheaper.

In the design realm, CAD-CAM (Computer Aided Design – Computer Aided Manufacturing) has very much become part of the jewelry industry. We utilize that a bit, but we are old-fashioned. We still like to draw things on paper and visualize them in our heads. We appreciate the technology, but we choose which new advances work best for us.

The holidays are approaching and people will be buying gifts. What’s in demand these days?

One of the latest trends we are seeing is long necklaces and multiple long necklaces worn together. We are also starting to see again large pendants hanging off the long chains. Pearls have been very strong for years, but these are not necessarily the traditional white pearls. We see a lot of multicolored pieces. There’s one type of strand called “multinational.” It has golden pearls from Indonesia, white pearls from Australian and New Zealand seas, and black and grey Tahitian pearls. Those are all natural colors. Such a piece works with everything because it has so many colors. For us, the holiday period is like three or four months rolled into one. We kind of tread water for most of the year and then make money at Christmas time.

To what do you attribute the longevity of Peñaloza & Sons?

My father was very conservative in the way he did business. Profits were plugged back into the business. We learned from him. We own our building and our inventory. Should things slow down, I don’t have a big bank note to repay. We are also very family-oriented here. We care about our employees and try to help them with their concerns. Many have been with us for years. It helps with the continuity of the business.

We also get to know our customers, their lifestyles and needs in order to design the best piece of jewelry for them. Most of our customers have been coming to us for years. For one woman we made four wedding rings for her four weddings, each ring better than the previous one.

Any advice for the jewelry-buying public?

First, if you don’t trust your jeweler, you have the wrong jeweler. It’s so easy for a jeweler to take advantage of people. Second, if you can afford it, buy the larger, more valuable stone. There’s little markup on those, and they will appreciate better. Also, don’t be afraid of colored stones.

How about gold?

Everything we do here is in 18-karat gold. It has a richer, deeper color than the 14-karat, which is brassier. A properly made piece in 18-karat gold or in platinum, even though they are softer metals, will outwear a piece made in 14-karat or 10-karat.

I would caution against buying jewelry solely for investment purposes. Choose something you’ll enjoy and can pass to the next generation. Should you need to sell it one day, however, you’ll probably find it has appreciated in value.

0 Comments